Anúncios

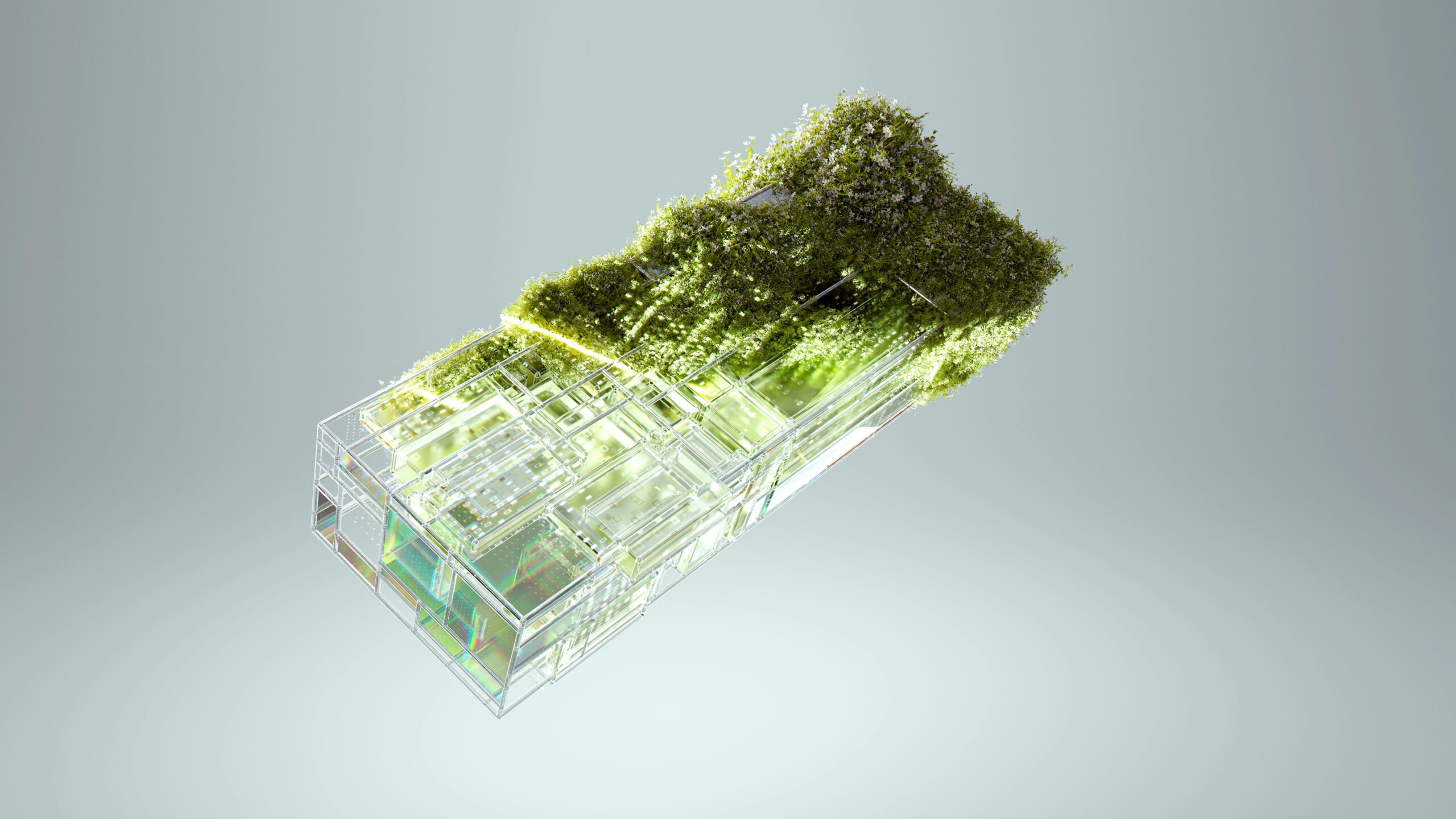

Energy loop integration represents a transformative approach to modern operations, combining resource management with technological innovation to unlock unprecedented levels of efficiency and sustainability in today’s competitive business landscape.

🔄 Understanding the Energy Loop Integration Concept

Energy loop integration is fundamentally about creating circular systems where energy flows seamlessly between different operational components, minimizing waste and maximizing output. This approach transforms traditional linear energy consumption models into dynamic, self-reinforcing cycles that benefit both operational efficiency and environmental sustainability.

Anúncios

At its core, energy loop integration involves capturing energy that would otherwise be lost or wasted in one process and redirecting it to power another. This creates a symbiotic relationship between different operational elements, where the output of one system becomes the input for another, establishing a continuous cycle of energy optimization.

The concept extends beyond simple recycling or reuse. It encompasses intelligent monitoring systems, predictive analytics, and automated control mechanisms that ensure energy flows are optimized in real-time. This holistic approach considers not just the immediate energy savings but the entire lifecycle impact of operational decisions.

Anúncios

💡 Core Components of Effective Energy Loop Systems

Implementing successful energy loop integration requires understanding and coordinating several essential components that work together to create seamless operations. Each element plays a critical role in maintaining the integrity and efficiency of the entire system.

Smart Monitoring Infrastructure

The foundation of any energy loop system is comprehensive monitoring capability. Advanced sensors and IoT devices track energy consumption, generation, and flow across all operational touchpoints. These systems collect real-time data on temperature, pressure, voltage, current, and numerous other parameters that influence energy efficiency.

Modern monitoring infrastructure goes beyond simple measurement. It incorporates machine learning algorithms that identify patterns, predict anomalies, and suggest optimizations based on historical data and current conditions. This predictive capability enables proactive adjustments rather than reactive responses to energy inefficiencies.

Integration Control Systems

Control systems serve as the brain of energy loop operations, processing data from monitoring infrastructure and making instantaneous decisions about energy distribution. These systems coordinate multiple energy sources, storage solutions, and consumption points to maintain optimal balance throughout the operational cycle.

Advanced control platforms utilize artificial intelligence to learn from operational patterns and continuously improve decision-making algorithms. They can automatically adjust energy flows based on demand forecasts, weather conditions, equipment status, and numerous other variables that impact energy efficiency.

Energy Storage Solutions

Storage capabilities are crucial for managing the temporal mismatch between energy generation and consumption. Battery systems, thermal storage, compressed air systems, and other technologies buffer energy during periods of excess production for use during peak demand or production shortfalls.

Modern energy storage solutions integrate seamlessly with control systems to optimize charging and discharging cycles based on energy prices, demand forecasts, and operational requirements. This strategic storage management significantly enhances overall system efficiency and economic performance.

🏭 Implementation Strategies for Different Industries

Energy loop integration manifests differently across various industrial sectors, each with unique opportunities and challenges. Understanding sector-specific applications helps organizations tailor implementation strategies to their particular operational contexts.

Manufacturing Sector Applications

Manufacturing facilities present exceptional opportunities for energy loop integration due to their diverse energy-intensive processes. Waste heat from furnaces, compressors, and other equipment can be captured and redirected to heating systems, preheating processes, or even generating additional electricity through cogeneration systems.

Production scheduling can be optimized based on energy availability and cost, shifting energy-intensive operations to periods of low electricity prices or high renewable energy generation. Smart manufacturing systems coordinate machine operations, climate control, lighting, and auxiliary systems to minimize total energy consumption while maintaining production targets.

Commercial Building Integration

Modern commercial buildings function as complex energy ecosystems where heating, cooling, lighting, and equipment loads must be balanced efficiently. Energy loop integration in this context involves coordinating HVAC systems with building occupancy patterns, weather conditions, and energy pricing to minimize consumption without compromising comfort.

Intelligent building management systems can redirect waste heat from data centers or refrigeration equipment to provide space heating or domestic hot water. Solar panels, energy storage, and grid connections form integrated systems that optimize energy sources based on real-time conditions and forecast demand.

Data Center Optimization

Data centers represent some of the most energy-intensive operations in the modern economy, making them ideal candidates for aggressive energy loop integration. Cooling systems account for significant portions of data center energy consumption, creating substantial opportunities for waste heat recovery and utilization.

Advanced data centers integrate cooling systems with local heating networks, greenhouses, or industrial processes that can utilize waste heat productively. Computing workloads can be dynamically allocated based on energy availability, shifting processing to locations or times with optimal energy conditions.

📊 Measuring Success: Key Performance Indicators

Effective energy loop integration requires clear metrics to assess performance, identify improvement opportunities, and demonstrate value to stakeholders. Comprehensive measurement frameworks track multiple dimensions of system performance.

- Energy Utilization Efficiency (EUE): Measures the percentage of total energy input that performs useful work versus losses

- Circular Energy Coefficient: Quantifies how much energy is recaptured and reused within operational loops

- Peak Demand Reduction: Tracks decreases in maximum power draw through load shifting and storage

- Carbon Intensity Metrics: Monitors emissions per unit of production or service delivered

- Economic Return on Energy Investment: Calculates financial returns from energy efficiency investments

- System Response Time: Measures how quickly integrated systems adapt to changing conditions

- Reliability and Uptime Scores: Assesses operational continuity and system availability

These metrics should be tracked continuously and reported regularly to maintain organizational focus on energy optimization. Benchmarking against industry standards and historical performance helps contextualize results and identify areas requiring attention.

🚀 Advanced Technologies Driving Integration Innovation

Emerging technologies are rapidly expanding the possibilities for energy loop integration, enabling increasingly sophisticated and efficient systems. Understanding these technological trends helps organizations prepare for future implementation opportunities.

Artificial Intelligence and Machine Learning

AI algorithms transform energy management from rule-based systems to adaptive, learning platforms that continuously improve performance. Machine learning models analyze vast datasets to identify subtle patterns and optimization opportunities that human operators might miss.

Predictive maintenance powered by AI prevents equipment failures that disrupt energy loops, while demand forecasting enables proactive energy management. Neural networks can optimize complex multi-variable systems in real-time, balancing competing objectives like cost, emissions, and reliability simultaneously.

Blockchain for Energy Transactions

Blockchain technology enables transparent, automated energy trading within integrated systems. Smart contracts can automatically execute energy transactions between different operational units or even separate organizations based on predefined conditions and real-time availability.

This decentralized approach to energy management supports microgrids and peer-to-peer energy sharing, expanding integration opportunities beyond traditional organizational boundaries. Blockchain-based systems ensure transaction integrity while reducing administrative overhead associated with energy management.

Digital Twin Technology

Digital twins create virtual replicas of physical energy systems, enabling simulation, testing, and optimization without disrupting actual operations. Engineers can model various integration scenarios, predict outcomes, and identify optimal configurations before implementing changes in real systems.

These virtual models continuously update based on real-world performance data, maintaining accurate representations of system behavior under various conditions. Digital twins accelerate innovation cycles and reduce the risk associated with implementing new integration strategies.

⚡ Overcoming Implementation Challenges

Despite its substantial benefits, energy loop integration presents several challenges that organizations must address strategically. Recognizing these obstacles early and developing mitigation strategies improves implementation success rates.

Initial Investment Requirements

Comprehensive energy loop integration often requires significant upfront capital for sensors, control systems, storage solutions, and infrastructure modifications. These costs can create budget constraints, especially for smaller organizations or those with limited capital availability.

Phased implementation approaches help manage financial requirements by prioritizing highest-return opportunities first. Energy service companies and performance contracting arrangements can provide alternative financing models that align costs with realized savings over time.

Technical Complexity and Integration

Modern facilities often contain equipment from multiple vendors using different communication protocols and control standards. Integrating these disparate systems into cohesive energy loops requires technical expertise and sometimes middleware solutions to bridge compatibility gaps.

Standardization initiatives and open protocols are gradually easing integration challenges, but significant technical hurdles remain. Organizations should invest in skilled personnel or partner with experienced integrators who understand both energy systems and information technology.

Organizational Change Management

Energy loop integration frequently requires changes to operational procedures, responsibilities, and decision-making processes. Resistance to these changes can undermine even technically sound implementations if stakeholders don’t understand or support the initiative.

Successful implementations emphasize training, clear communication of benefits, and inclusive planning processes that give operational staff ownership over energy optimization efforts. Demonstrating quick wins early in the process builds momentum and stakeholder confidence.

🌍 Environmental and Economic Benefits

The compelling case for energy loop integration rests on its dual capacity to deliver environmental sustainability and economic value simultaneously. These complementary benefits make energy optimization increasingly central to corporate strategy.

Environmental benefits include substantial reductions in greenhouse gas emissions through decreased fossil fuel consumption and improved efficiency. Energy loop systems reduce waste generation, conserve natural resources, and minimize environmental impact across operational lifecycles.

Economic advantages manifest through direct energy cost reductions, decreased maintenance requirements from optimized equipment operation, and enhanced operational resilience. Organizations often experience improved competitiveness through lower operating costs and enhanced reputation among environmentally conscious customers and stakeholders.

Regulatory compliance becomes easier as governments worldwide implement stricter energy efficiency standards and carbon reduction requirements. Early adopters of energy loop integration position themselves advantageously for future regulatory environments while potentially accessing incentives and preferential treatment.

🎯 Strategic Planning for Long-Term Success

Maximizing the benefits of energy loop integration requires strategic planning that extends beyond initial implementation to encompass continuous improvement and adaptation to evolving conditions.

Comprehensive energy audits identify current consumption patterns, waste streams, and integration opportunities specific to each facility. These assessments establish baseline performance metrics and prioritize improvement initiatives based on potential impact and implementation feasibility.

Long-term roadmaps should anticipate technological evolution, regulatory changes, and shifting business requirements. Modular system designs that accommodate future expansions and upgrades protect initial investments while maintaining flexibility for incorporating emerging innovations.

Stakeholder engagement processes ensure alignment between energy optimization initiatives and broader organizational objectives. Executive sponsorship, cross-functional coordination, and clear communication channels support sustained momentum even as priorities and personnel change over time.

🔮 Future Directions and Emerging Opportunities

The field of energy loop integration continues evolving rapidly, with emerging trends suggesting even greater potential in coming years. Organizations that monitor these developments position themselves to leverage new capabilities as they mature.

Hydrogen technologies are expanding energy storage and transportation options, particularly for industrial applications requiring high energy density. Green hydrogen produced from renewable electricity can store excess generation for later use or serve as clean fuel for processes currently dependent on fossil fuels.

Vehicle-to-grid integration transforms electric vehicles from simple energy consumers into distributed storage assets that can support facility energy management. Fleet vehicles can absorb excess renewable generation during the day and provide power back to facilities during evening peak periods.

Quantum computing promises to solve complex optimization problems that currently challenge even advanced classical computers. These capabilities could enable real-time optimization of massive, interconnected energy systems that exceed current computational limits.

🏆 Building Competitive Advantage Through Energy Excellence

Organizations that master energy loop integration create sustainable competitive advantages that extend well beyond simple cost savings. Operational excellence in energy management signals broader capabilities that attract customers, investors, and talent.

Enhanced reliability and resilience resulting from diversified, integrated energy systems reduce vulnerability to grid disruptions, fuel price volatility, and supply chain disruptions. This operational stability supports superior customer service and protects revenue streams during challenging conditions.

Innovation capabilities developed through energy integration efforts often transfer to other operational domains, fostering cultures of continuous improvement and technological sophistication. Organizations become more adaptable and better positioned to capitalize on emerging opportunities across their business portfolios.

Leadership in energy efficiency and sustainability strengthens brand reputation and stakeholder relationships in an era of increasing environmental consciousness. This reputational value translates into tangible business benefits through customer loyalty, investor interest, and easier regulatory approvals for expansion and development projects.

The journey toward maximizing efficiency through energy loop integration represents both an operational imperative and strategic opportunity for forward-thinking organizations. By embracing comprehensive integration approaches, leveraging emerging technologies, and maintaining focus on continuous improvement, businesses can achieve remarkable efficiency gains while contributing meaningfully to environmental sustainability. The power of seamlessly integrated energy operations extends throughout organizational performance, creating value that compounds over time and positions adopters as leaders in their respective industries.

Toni Santos is a regenerative-design researcher and permaculture writer exploring how ecological farming, resource cycles, soil restoration science and sustainable community models shape living systems for the future. Through his investigations into land-regeneration, community design and ecological intelligence, Toni examines how healing earth and society can be co-designed for vitality, resilience and meaning. Passionate about land-wisdom, systems thinking and ecological praxis, Toni focuses on how living systems evolve in partnership with nature and community. His work highlights the convergence of soil biology, design theory and collective action — guiding readers toward lives and places that regenerate rather than only sustain. Blending permaculture, ecological science and community design, Toni writes about the ecology of regeneration — helping readers understand how land, culture and design interweave in the creation of thriving systems. His work is a tribute to: The renewal of soil, ecosystem and community in living systems The dynamics of cycles, flows and regenerative infrastructure The vision of communities designed with nature, possibility and future in mind Whether you are a designer, farmer or ecological thinker, Toni Santos invites you to explore the regeneration of land, system and society — one habitat, one cycle, one community at a time.